The Important Attributes of Excavator That Keep It a Must-Have Device

Excavators are indispensable in the construction and landscaping sectors. Their functional accessories enable for a variety of jobs, from digging to demolition. Furthermore, they flaunt remarkable excavating depth and reach, powered by robust engines. Driver comfort and portable designs enhance functionality in different settings. Nevertheless, what genuinely sets excavators apart are their sophisticated hydraulic systems and durability. Understanding these functions can clear up why they are taken into consideration crucial tools on any kind of task website.

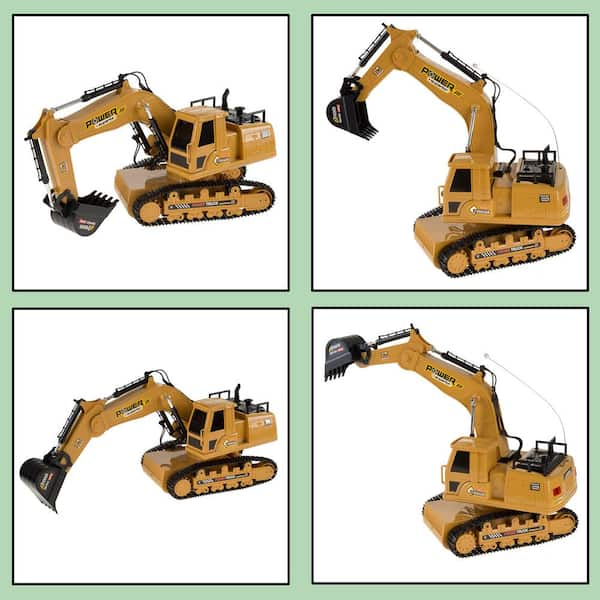

Versatile Add-ons for Boosted Functionality

Although excavators are powerful equipments on their very own, the addition of versatile add-ons considerably boosts their capability. These accessories transform a basic excavator right into a multi-purpose tool, suitable for a selection of tasks. Pails, for instance, been available in numerous sizes and shapes, enabling operators to dig, scoop, and relocate materials effectively. Hydraulic thumbs can be included for improved gripping and handling of large things, such as logs or rocks.Furthermore, specialized add-ons like augers and breakers enable for drilling and demolition work, expanding the excavator's utility on building and construction websites. remote control excavator. Grapples are one more alternative, suitable for relocating and arranging particles. This flexibility not just enhances efficiency yet likewise lowers the need for multiple makers, saving time and expenses. By gearing up excavators with the best accessories, drivers can tackle diverse jobs, making them essential in the construction market

Superior Excavating Depth and Reach

Excavators are designed with remarkable excavating deepness and reach, enabling them to steer in limited areas and access hard-to-reach locations. This capability is important for numerous building and construction and excavation projects, where standard machinery may fail. With adjustable boom arms and extendable tracks, excavators can quickly navigate uneven surface while keeping stability.The digging depth can differ considerably amongst versions, usually varying from 10 to 25 feet, relying on the style and function. This feature allows drivers to excavate foundations, trenches, and other deep frameworks efficiently. Furthermore, the reach of an excavator allows for exact digging and product handling without repositioning the machine often, saving time and labor costs.Ultimately, the premium digging deepness and reach of excavators make them indispensable for experts seeking to complete complicated tasks with precision and performance. Their versatility improves productivity on work websites, showcasing them as an important tool in modern construction.

Powerful Engine Performance

Powerful engine efficiency plays a crucial role in the capacities of an excavator when it comes to effectiveness and efficiency on building sites. A robust engine produces substantial horsepower, allowing the maker to take on durable tasks with convenience - remote control excavator. This toughness translates right into faster cycle times, enabling drivers to complete projects much more quickly.Additionally, effective engines offer the necessary torque to handle tough surfaces and differed loads, guaranteeing that the excavator can execute effectively under different conditions. Whether it is lifting, digging, or moving materials, the engine's performance straight affects the general functional efficiency of the machine.Furthermore, developments in engine innovation have led to enhanced gas efficiency, minimizing operational costs while maintaining power output. Ultimately, the engine's efficiency functions as the backbone of an excavator, affirming its standing as an essential device in the building and construction sector

Advanced Hydraulic Equipments

Enhanced Raising Capability

A substantial enhancement in lifting ability can be associated to sophisticated hydraulic systems found in contemporary excavators. These systems make use of high-pressure liquid to produce higher pressure, permitting operators to lift larger lots effortlessly. The design behind these hydraulics assurances peak efficiency, offering an excellent power-to-weight proportion that boosts total effectiveness. Because of this, excavators can deal with requiring jobs, such as lifting big products or tools, without endangering stability. Furthermore, the durable layout of hydraulic parts contributes to raised longevity and reliability, making them appropriate for numerous building and construction settings. This boosted lifting capability not only decreases the moment required for projects yet likewise lessens the need for extra equipment, proving important for both productivity and cost-effectiveness in the building industry.

Boosted Precision Control

Traditional excavators typically had a hard time with accuracy, contemporary hydraulic systems have changed control systems, allowing operators to implement jobs with remarkable accuracy. These innovative systems make use of symmetrical control valves that permit smoother and more receptive motions, considerably minimizing the margin for error. Operators can now finely tune the excavator's movements, making it easier to navigate limited areas and take care of fragile materials. Enhanced responses systems further notify drivers of real-time efficiency, guaranteeing perfect control in between the equipment and operator. This boosted accuracy not just boosts efficiency but additionally enhances safety on work websites, minimizing the danger of crashes. As an outcome, modern excavators outfitted with innovative hydraulic systems are very useful tools for construction and excavation tasks requiring careful precision.

Operator Convenience and Visibility

Operator convenience and exposure are essential parts in the style of contemporary excavators (remote control excavator). Attributes such as ergonomic seat layout, boosted presence alternatives, and efficient control formats considerably improve the driver's experience and performance. Focusing on these elements warranties that operators can work successfully and safely in different conditions

Ergonomic Seat Style

Comfort and visibility are paramount in excavator design, with the ergonomic seat playing a vital role in improving the driver's experience. An ergonomic seat is engineered to sustain the operator's body, lowering tiredness during lengthy hours of procedure. Flexible functions, such as seat elevation, backrest angle, and lumbar support, satisfy individual choices and advertise suitable stance. These changes enhance comfort and enable the operator to keep concentrate on jobs without discomfort. Furthermore, a well-designed seat can offer far better side assistance, permitting smoother maneuvering when the excavator functions. This thoughtful layout not only enhances performance but also adds to general safety, guaranteeing that drivers can execute their responsibilities properly and efficiently.

Improved Visibility Functions

The style of an excavator extends beyond simply the seat, with enhanced visibility features playing a considerable function in operator comfort and general security. Big home windows and purposefully located mirrors give drivers with a clear sight of their surroundings, decreasing unseen areas. This style factor to consider enables for far better spatial understanding, which is crucial in hectic workplace. On top of that, several excavators incorporate rearview electronic cameras and advanced surveillance systems that assist operators in navigating limited areas. The combination of these presence includes not just promotes security however additionally minimizes operator exhaustion by enabling less complicated monitoring of workplace. Ultimately, boosted visibility adds to a lot more reliable operations and aids assure that excavators can execute their jobs successfully and securely.

Control Format Performance

While maneuvering facility work sites, an effective control layout substantially enhances both driver convenience and visibility. A well-designed control arrangement warranties that drivers can access vital features with minimal effort, reducing exhaustion throughout lengthy hours. Ergonomic joystick placements and user-friendly button plans permit for seamless procedure, enabling drivers to preserve concentrate on the job handy. In addition, clear presence of both the workplace and the control panel is crucial for safety and security and precision. Modern excavators commonly incorporate adjustable seats and control setups to accommodate different driver choices, further improving convenience. Ultimately, a thoughtfully developed control design not just improves performance however likewise fosters a more secure working setting by enabling drivers to respond swiftly to altering conditions.

Compact Layout for Urban Environments

As metropolitan building websites typically face room constraints, a compact style ends up being crucial for excavators running in these settings. These devices are engineered to navigate tight rooms, permitting for reliable ability to move in congested work sites. A reduced footprint allows them to function carefully to existing structures, minimizing disruption and taking full advantage of productivity.The portable design commonly consists of shorter tracks and a tighter turning distance, facilitating procedure in narrow alleys and confined locations. In addition, lightweight products add to reduce of transportation, making it less complex to relocate the excavator from one location to one more within the metropolitan landscape.Additionally, lots of small excavators are equipped with features such as extendable arms and functional add-ons, enhancing their capability while keeping a small dimension. This versatility enables drivers to deal with a range of tasks, from digging to demolition, all while fitting flawlessly right into the restraints of urban environments.

Durability and Maintenance Considerations

Sturdiness stands as an essential variable in the efficiency and long life of excavators, particularly in demanding urban environments. These equipments undergo rigorous problems, including varying soil kinds, extreme temperature levels, and high-frequency use. High-grade materials and robust construction are required for making sure that excavators can hold resource up against these obstacles without endangering functionality.Regular maintenance is similarly vital in protecting toughness. Arranged assessments, prompt oil modifications, and the substitute of used parts add significantly to an excavator's life-span. Operators should additionally take notice of hydraulic systems, tracks, and undercarriages, as these parts usually birth the brunt of wear and tear.Investing in durable excavators with substantial upkeep plans improves integrity and reduces downtime, ultimately resulting in boosted productivity on building sites. Consequently, understanding the interaction in between toughness and maintenance is essential for anybody considering the procurement of an excavator for metropolitan jobs.

Frequently Asked Concerns

Exactly How Do Excavators Contrast to Other Construction Tools?

Excavators stand out among construction tools because of their convenience, making it possible for jobs such as grading, digging, and lifting. Compared to others, their hydraulic capabilities offer better efficiency and power, making them indispensable on different job websites.

What Safety Features Are Consisted Of in Modern Excavators?

Modern excavators include various security functions, including rollover defense systems, alarms, and progressed presence enhancements. These aspects collaborate to lessen risks, making certain driver safety while boosting effectiveness on construction websites look these up and other requiring settings.

Can Excavators Be Made Use Of in Wintertime Issues?

Excavators can indeed be used in winter months conditions, supplied they are equipped with ideal winter attachments and safety measures are taken. Appropriate maintenance and changes improve their performance, making certain reliable operation despite tough weather conditions.

What Is the Typical Life-span of an Excavator?

The average lifespan of an excavator generally ranges from 7,000 to 10,000 hours of operation. This duration can substantially depend upon maintenance methods, running conditions, and the certain design's durability and layout features.

Exactly how Do I Select the Right Excavator Dimension for My Task?

Choosing the appropriate excavator dimension includes examining job scope, website problems, and material kinds. Consider factors like reach, deepness demands, and weight capability to assure maximum efficiency and safety throughout operation. Size matters substantially in job success. In addition, the reach of an excavator permits for accurate digging and material handling without repositioning the machine often, conserving time and labor costs.Ultimately, the remarkable excavating depth and reach of excavators make them crucial for specialists looking for to complete complex tasks with precision and effectiveness. Comfort and visibility are extremely important in excavator layout, with the ergonomic seat playing an important role in enhancing the driver's experience. The layout of an excavator extends beyond just the seat, with enhanced visibility features playing a considerable role in driver comfort and total security. Modern excavators commonly integrate adjustable seating and control settings to suit different driver choices, my link additionally boosting comfort. Lightweight products contribute to relieve of transportation, making it simpler to move the excavator from one location to one more within the metropolitan landscape.Additionally, lots of compact excavators are equipped with attributes such as functional accessories and extendable arms, improving their capability while maintaining a small dimension.